Individual Solutions

FLOOR PAVEMENT

Individual Solutions

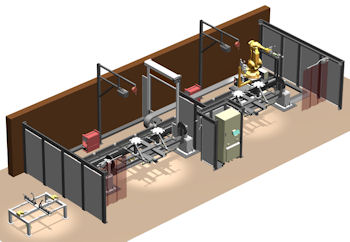

5-STATION-SYSTEM

Robolution is a supplier in the field of system engineering. The many years of experience, especially in the field of automated welding technology, is reflected in the many and successful solutions offered by the customers. Standard robotic welding system, as well as individually tailored system concepts are a hallmark of Robolution.

Robolution is not limited to welding applications, but also implements any additional peripherals. Whether handling, further processing or material flow; The Robolution team will also find the best solution for you.

5-Station System

A concept with a 5-station system is often used when short cycle times are required. The welding robots used (in this case 6 pieces) share the required welding tasks. Using a handling robot, the welded component can then be removed in the following station. Thus, an empty device is available to the operator in the insertion area. The 5-station table can be equipped with rigid mountings or, as in this case, with 5 horizontal rotary axes of type TurnRot.

- 5-station table with 5 TurnRot positioners

- 6 welding robots and 1 hand-held robot

- Automatic component removal and single component assembly

- Component handling using state-of-the-art gripping and vacuum technologyIntegrated vibrator for single parts feed

- Highest productivity