FLEX-FAB FT-DS

FLEX-FAB XFT

FLEX-FAB XHS300/600

FLEX-FAB LIGHT

FLEX-FAB COBOT LIGHT

FLEX-FAB COBOT MOBILE

AN OPTIMAL RANGE FOR SMALL TO MEDIUM PARTS

With our FLEX-FAB robotic welding cells, we have engineered newer, more advanced and more affordable robotic systems to support manufacturers of all sizes – from the small shop owner to medium part supplier.

An automated robotic welding cell can help you speed up production, reduce labour costs, improve weld integrity and consistency, and reduce downtime.

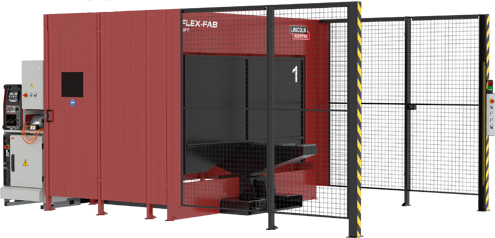

FLEX-FAB — FT-DS

Benefits

- Ideal for welding small to medium-sized parts that do not require rotation or repositioning

- Minimal installation

- Improves productivity, quality and safety

Examples of Manufactured Parts

- Enclosures and boxes, such as electrical panels

- Food service equipment

- Miscellaneous: small brackets, handrails, education institutions

Scope of delivery

- ABB robot IRB 1660iD

- fixed table (2 work envelopes 500 x 500 x 300mm/ 300kg)

- Lincoln Power Wave R450

- Cleaning station ABB TC 2013

- Safety Equipment

- Documentation/ CE

- Lincoln Checkpoint

Options

- ABB TSC

- Weldguide IV

- Roof

- Optimized wire feedeing system

- Air treatment unit

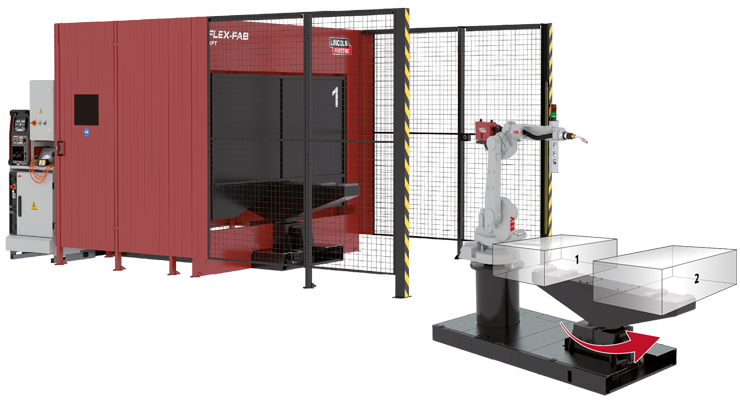

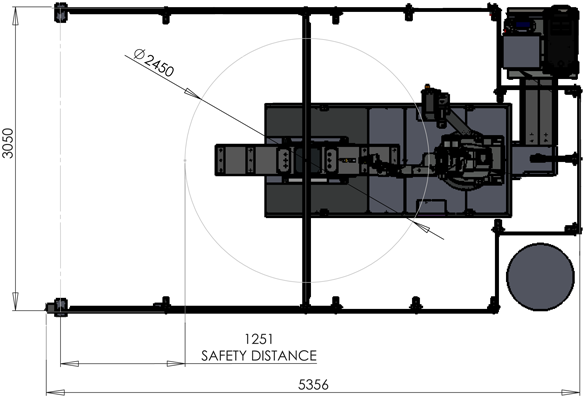

FLEX-FAB — XFT

Benefits

- Single load and unload area with two independent work zones

- Turntable system provides 180-degree rotating work area for increased throughput efficiency

- Ideal for small- to medium-sized parts not requiring reorientation

- Promotes optimum use of floor space

- Servo-driven positioner has no mechanical components and is nearly maintenance-free

Examples of Manufactured Parts

- Construction equipment, such as subassemblies, cylinders

- Heat exchangers

- AC ventilation

- Foodservice equipment

- Miscellaneous: brackets, satellite dish brackets, rebar brackets, couplers, stair treads

Scope of delivery

- ABB robot IRB 1660iD

- ABB IRBP-C500 (∅2.450mm/ 2 work envelopes 1.200 x 700 x 300mm/ 500kg)

- Lincoln Power Wave R450

- Cleaning station ABB TC 2013

- Safety Equipment

- Documentation/ CE

- Lincoln Checkpoint

Options

- ABB TSC

- Weldguide IV

- Roof

- Optimized wire feedeing system

- Air treatment unit

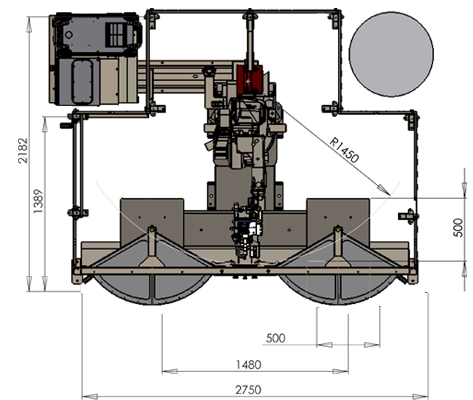

FLEX-FAB — XHS300/600

Benefits

- Enhance part production by improving productivity, quality and safety

- Dual zone with a rear-mounted robot on an H-Frame positioner

- 180-degree rotation for single load/unload access point

- Smaller arm and system footprint produces higher throughput rates

- Optimized to maximize the work envelope of the robot

Examples of Manufactured Parts

- Agricultural Equipment

- Recreational Vehicles: cart frame, hitches and components

- Miscellaneous: office furniture, door window frames, water heaters

Scope of delivery

- XHS300

- ABB robot IRB 1660iD

- ABB H-Frame positioner IRBP-R300 (∅1.000mm/ L=1.600mm/ 300kg)

- XHS600

- ABB robot IRB 2600iD

- ABB H-Frame positioner IRBP-R600 (∅1.200mm/ L=2.000mm/ 600kg)

- Lincoln Power Wave R450

- Cleaning station ABB TC 2013

- Safety Equipment

- Documentation/ CE

- Lincoln Checkpoint

Options

- ABB TSC

- Weldguide IV

- Roof

- Optimized wire feedeing system

- Air treatment unit

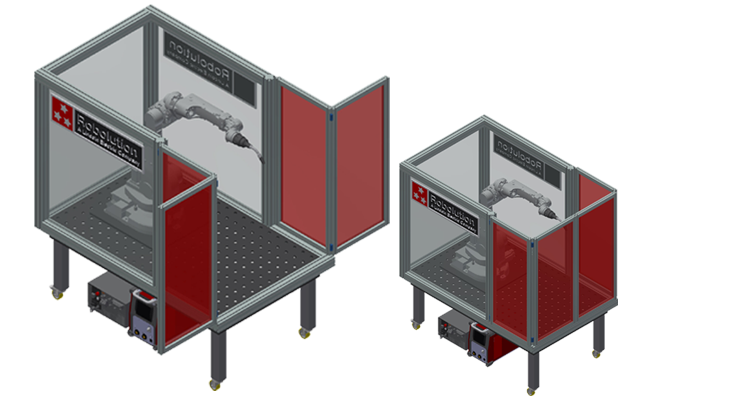

FLEX-FAB — LIGHT

Benefits

- xx

Examples of Manufactured Parts

- xx

Scope of delivery

- ABB robot IRB 1660iD-6/1.45

- welding table Professional 750 (2.000 x 1.200 x 300mm)

- Lincoln Power Wave R450

- Safety Equipment

- Documentation/ CE

Options

- xx

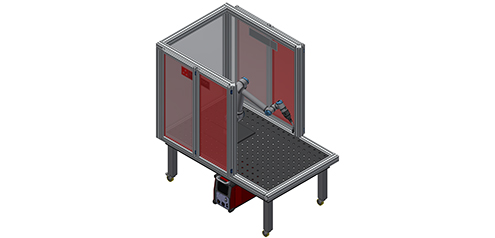

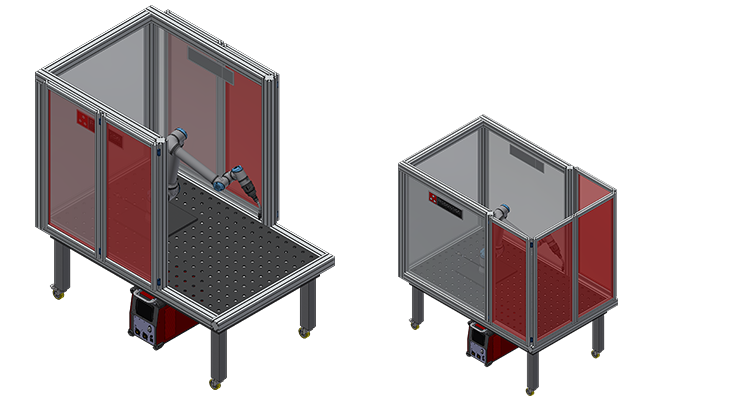

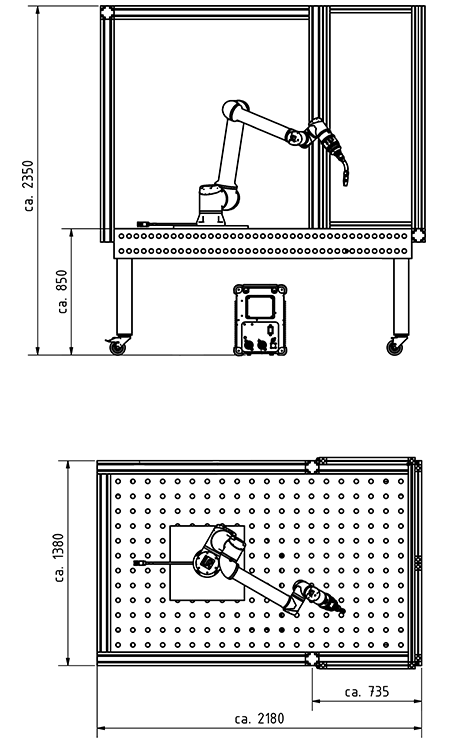

FLEX-FAB — COBOT LIGHT

Benefits

- xx

Examples of Manufactured Parts

- xx

Scope of delivery

- Installed with robots from Fanuc and Universal Robot

- welding table Professional 750 (2.000 x 1.200 x 300mm)

- Lincoln Power Wave R450

- Safety Equipment

- Documentation/ CE

Options

- xx

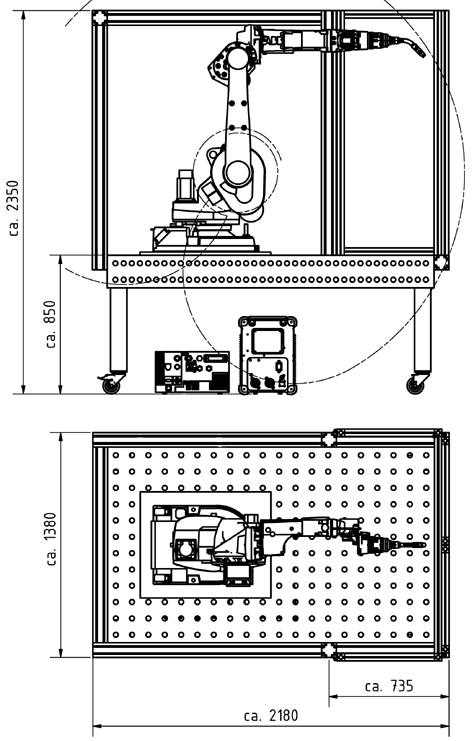

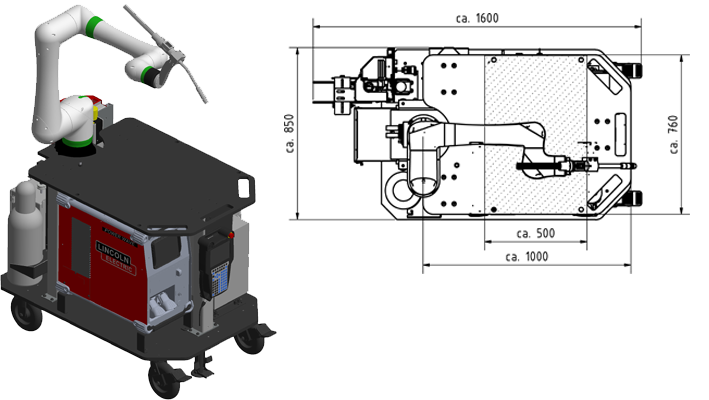

FLEX-FAB — COBOT MOBILE

Ideal for manufacturers of high-mix and low-volume parts, the FLEX-FAB Cobot can be easily moved to the part you need to weld quickly and easily, all while safely operating in tandem with your production staff.

Ideal for:

- High-mix and low-volume parts

- Large and bulky parts that do not fit in a traditional robotic welding cell

- Flexible shops that need mobility in their welding process

Scope of delivery

- Power Wave® R450 power source

- Installed with robots from Fanuc and Universal Robot

- AutoDrive® wire feeder

- FANUC single axis positioner

- Magnum® PRO robotic torch

- Heavy-duty caster system

- Integrated gas tank stand

- Kickstand cart stabilizer

- Hand guidance unit (optional)

Safety features

Power and force limiting sensors, speed and separation monitoring with soft impact design and sensing technology

Easy to program

Minimal techsavviness required makes training and learning how to use simple and straightforward

Adaptable to your needs

Easy to re-deploy anywhere you need it on high-mix, low-volumes of dedicated parts saving you valuable floor space

Options

-

Modular Tooling Inserts

- Direct-mount modular tooling plate for easy build-up and tear-down of tooling

- 05/8 holes x 2” grid pattern

- Use with existing tooling or clamp and block kit

- Modular Clamp & Block Kit

- All-in-one modular fixturing kits complete with reusable clamps, blocks, angles, stops, bolts, etc.

- Design assistance available

-

Fume Extraction

- Integrated fume control with large surface area coverage

- Adjustable extraction hose to flex with your parts